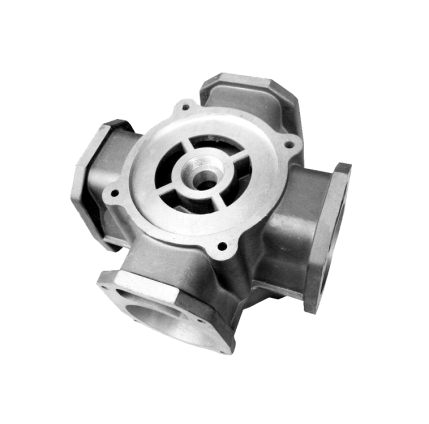

#1 DIE CASTING MANUFACTURER IN CHINA

Redstone Manufacturing’s die-casting facility in China is committed to delivering the best-in-class buying experience from start to finish. Continue reading on to learn more about our unique approach to the die-casting process, and how our US-based sales-staff can help you optimize tariff costs, and demystify the buying process of die-casting services in China.

DIE CASTING IN CHINA – SIMPLIFIED

THE LIST OF DIE CASTING COMPANIES IN CHINA IS ENDLESS...

With China’s die-casting industry consisting of more than 1,000 manufacturers spread out from Shanghai to Beijing, and Guangzhou, the process of selecting a die-casting vendor in China can be overwhelming. Here at Redstone Manufacturing, we simplify the buying process and reduce the risk of working with foreign manufacturers. With headquarters in the USA and die-casting manufacturing facilities in China, our buyers receive guaranteed delivery backed by a US-based company with a US-based sales force they can trust. Combined with Redstone Manufacturing’s supply chain, tariff consulting, and diverse die-casting production capabilities, the end result is significant cost savings and reduced risk during your die-casting process from start to finish.

OUR DIE CASTING FACILITY IN CHINA HAS THE FOLLOWING CAPABILITIES

| SIZES AVAILABLE | 0.050 kg to 50 kg |

| MATERIALS AVAILABLE | Aluminum, zinc, copper |

| Processes Available: | Pressure die casting in China |

| TOLERANCE | +/- 0.015″ (0.381 mm) |

| LEAD TIME | 8-12 weeks |

| SURFACE FINISHES AVAILABLE | Anodizing, Powder Coating |

China Die Casting: High-Precision, High-Volume Metal Casting Solutions

Redstone Manufacturing provides reliable access to leading china die casting factories that specialize in precision, efficiency, and cost-effective metal component production. Our engineering oversight combined with strong local partnerships ensures you receive world-class quality from top-tier suppliers. Whether you need prototype tooling, complex aluminum housings, or high-volume zinc components, Redstone delivers consistent performance backed by rigorous quality control.

Customers across industries rely on us as their trusted partner for die casting china solutions due to our technical expertise, competitive pricing, and seamless supply-chain management.

Die Casting Process Description

Die casting is a precision manufacturing process that injects molten metal—such as aluminum or zinc—into a steel mold under high pressure. This allows the production of durable, dimensionally accurate components with excellent mechanical properties and surface finishes.

Our workflow includes:

- Engineering review and design-for-manufacturing optimization

- Tooling development at a trusted china die casting factory

- Material selection based on strength, weight, and thermal requirements

- High-pressure die casting using advanced automated equipment

- Post-casting processes such as trimming, machining, and finishing

- Quality control including X-ray inspection, dimensional checks, and metallurgical testing

This fully integrated approach ensures that every component meets international tolerance, performance, and surface-quality standards.

Why Choose Redstone for Die Casting in China

Redstone is recognized as a reliable partner for sourcing components from a top china die casting company due to our engineering oversight and strict quality assurance. We provide:

- Access to vetted aluminum die casting manufacturer china partners

- Local quality teams to monitor production and perform inspections

- ISO-certified facilities using modern high-pressure machines

- Cost savings without sacrificing consistency or durability

- Expertise in complex geometries and thin-walled castings

- Strong supply-chain management for predictable delivery

- Engineering support for tooling, optimization, and validation

Our model gives you the cost advantages of china aluminium die casting with the security and transparency of Western-quality project management.

How to Order China Die Casting Services

- Share your design files

Submit CAD models, drawings, and material requirements. - Receive a detailed quote

We assess tooling, cycle time, secondary operations, and finishing needs. - Tooling and mold creation

High-quality steel molds are produced for long-term, stable operation. - Sampling and first-article approval

Parts are cast, inspected, and refined until approval is granted. - Full-scale production

The chosen die casting manufacturer china begins high-volume production. - Quality verification

Redstone performs on-site inspections and batch testing. - Packaging and worldwide shipping

Parts are carefully packaged and delivered according to your timeline.

Types of Die Casting Services Available

Our network supports multiple die casting materials and processes.

Aluminum Die Casting China

Lightweight, strong, corrosion-resistant components ideal for automotive, electronics, consumer products, and industrial machinery. Our china aluminum die casting partners specialize in intricate, high-strength parts.

Zinc Die Casting China

Excellent for complex, small parts with high dimensional accuracy and superior surface finish. Ideal for hardware, connectors, locks, and decorative components.

China Precision Die Casting

For tight-tolerance components requiring exceptional detail, thin walls, or demanding performance characteristics. Used for high-end electronics, aerospace components, and medical devices.

Multi-Cavity and High-Volume Tooling

Supports large production runs with consistent repeatability and low per-unit cost.

Available Finishes

Redstone offers a wide range of finishing options to enhance durability, functionality, and aesthetics:

- Shot blasting

- Vibratory polishing

- CNC machining

- Powder coating

- Anodizing

- Painting

- Plating (nickel, chrome, zinc)

- Laser engraving

- Custom finishing upon request

Applications of China Die Cast Components

Die castings from our china die casting factory partners are used across a variety of industries that require durability, lightweight materials, and high dimensional stability. Common applications include:

- Automotive housings and brackets

- Consumer electronics enclosures

- LED lighting components

- Aerospace fittings

- Industrial machinery parts

- Hydraulic and pneumatic components

- Tooling hardware

- Medical device components

- Structural supports and connectors

These applications benefit from the strength-to-weight advantages and precision of die-cast metals.

Advantages of Die Casting

Die casting provides several key benefits that make it ideal for high-volume production:

- Excellent dimensional accuracy and repeatability

- Ability to produce complex shapes and thin walls

- High strength and durability

- Smooth, detailed surface finishes

- Low per-unit production cost

- Fast cycle times for high-volume manufacturing

- Compatibility with aluminum, zinc, and magnesium alloys

Combined with Redstone’s engineering support and trusted china die casting company network, this method offers exceptional performance and cost efficiency.

Get updates from Redstone Manufacturing

Learn more about our metal manufacturing company

Changed from Brochure to Newsletter on 8/12/24