Mexico Foundry, Specializing in Steel Melting & Casting

Looking around for reliable foundries in Mexico? Redstone Manufacturing is not your traditional Mexican steel foundry. As a U.S.-based company with foundries in Mexico, we reduce the risk of working with foreign foundries and provide value-added services that impact your bottom line. Continue reading on to learn more about the Redstone Manufacturing difference.

Redstone Manufacturing

Foundries in Mexico, Headquarters in the U.S.A.

Did you know, there are over 100 steel foundries in Mexico spread out from Mexico City to Monterrey? The process of selecting a reliable Mexican steel foundry can be overwhelming for an organization with little overseas manufacturing experience.

At Redstone Manufacturing, we simplify the buying process and reduce the risk of outsourcing production to foundries in Mexico.

With headquarters in the USA and foundries in Mexico, our buyers receive guaranteed delivery backed by a US-based company with a US-based sales force they can trust.

Combined with Redstone Manufacturing’s supply chain, tariff consulting, and diverse production capabilities, the end result is significant cost savings and reduced risk during your manufacturing process from start to finish.

REDSTONE MEXICO FOUNDRY

ADDRESS

Available upon request

HOURS

Monday: 9am to 6pm

Tuesday: 9am to 6pm

Wednesday: 9am to 6pm

Thursday: 9am to 6pm

Friday: 9am to 6pm

DIVERSE MELTING & CASTING

SERVICES IN OUR MEXICO FOUNDRIES.

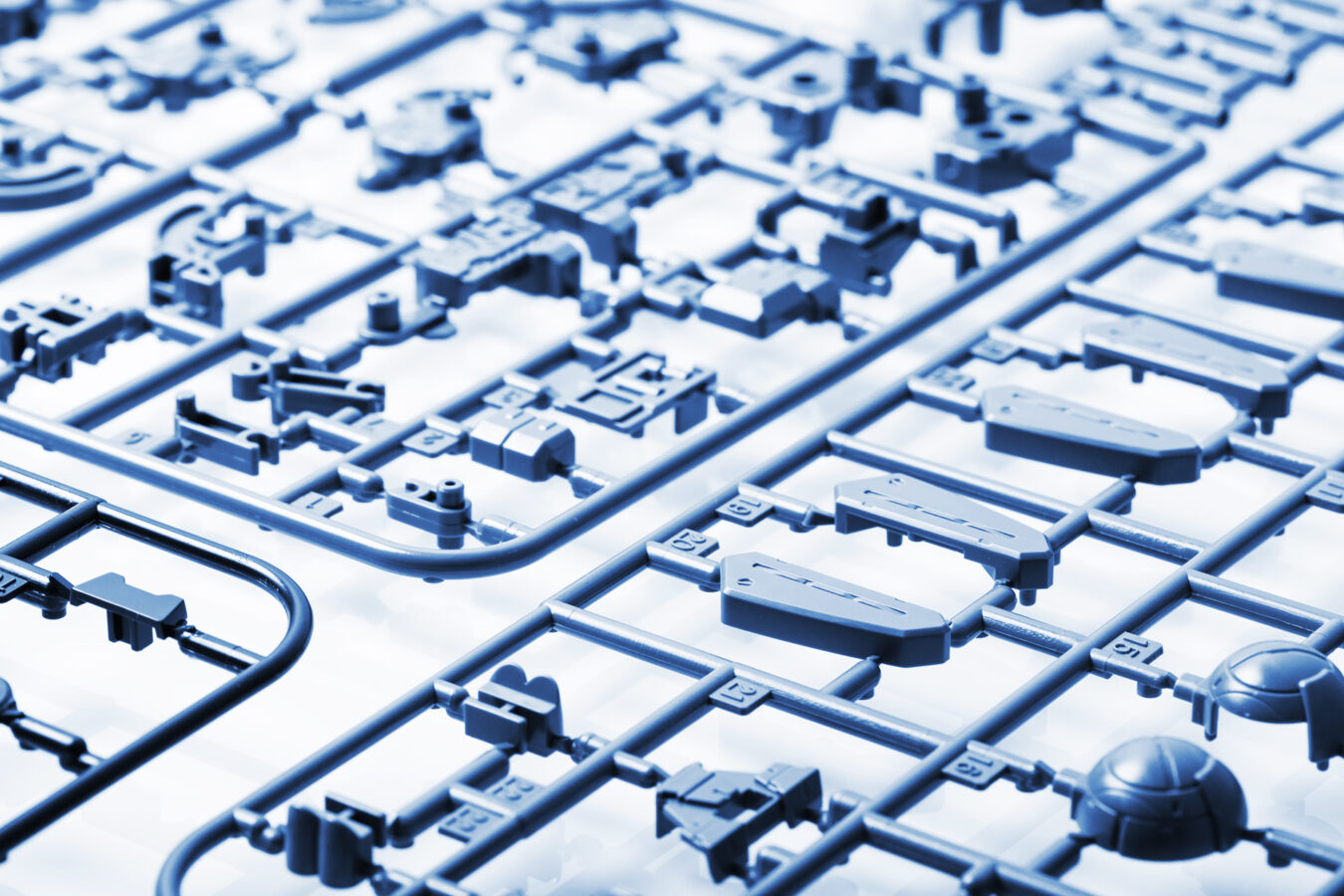

In addition to providing melting and casting services at our foundry in Mexico, we also provide metal fabrication services ranging from CNC Machining, Sheet Metal Fabrications, Metal Injection Molding, and Plastic Injection Molding.

Value Added Services At Our MEXICO Foundries

TARIFF & DUTY TAX CONSULTING

Discover the most optimal way to import by consulting with our tariff experts.

PRODUCT DESIGN CONSULTING

Analysis of 3D files, materials, surface finishes, and tolerances to ensure no production issues.

LANDED PRICE CALCULATION

All-inclusive estimates including tariffs, production costs, shipping, and more.

SAMPLES AT

NO CHARGE

Receive casting samples for your approval, prior to production and at no cost to you.

3RD PARTY

INSPECTIONS

Quality control and inspections prior to shipments are always included.

DELIVERY

GUARANTEE

Contractual agreements with Redstone Manufacturing USA provides you legal protection.

Mexico Foundries: High-Quality Casting Services

Redstone Manufacturing partners with leading foundries in Mexico to deliver reliable, durable, and cost-effective metal castings for industrial, automotive, and commercial applications. Our Mexico foundries services provide access to high-quality foundry companies in Mexico, ensuring precision, consistency, and timely delivery for both prototypes and large-scale production.

Foundry Process Description

Foundry operations involve melting metals and pouring them into molds to create components with specific shapes and mechanical properties. The process begins with pattern creation, followed by mold preparation using sand, investment, or permanent molds. Molten metal is then poured, allowed to cool, and the casting is removed, cleaned, and finished.

Redstone’s foundries in Mexico partners use advanced processes including:

- Sand casting for large and complex components

- Investment casting for precise, intricate parts

- Controlled cooling and heat treatment for strength

- Secondary machining, finishing, and quality inspection

- Dimensional verification to meet client specifications

This ensures every casting meets high standards of accuracy, durability, and quality.

Why Choose Redstone for Foundry Services in Mexico

Redstone Manufacturing is a trusted partner for foundries in Mexico because we provide:

- Access to vetted foundry companies in Mexico with proven capabilities

- Engineering support for design optimization and manufacturability

- Cost-effective production for prototypes and high-volume batches

- Expertise in cast iron, aluminum, steel, and specialty alloys

- Quality assurance with on-site inspections and audits

- Efficient supply chain and shipping

By working with Redstone, clients gain reliable access to Mexico foundries that deliver consistent quality at competitive prices.

How to Order Foundry Services

- Submit your design files

Include CAD models, material specifications, drawings, and tolerances. - Receive a detailed quotation

Redstone evaluates mold type, material, volume, and finishing requirements. - Prototype and mold preparation

Initial patterns and molds are developed to validate the design and process. - Sample production and approval

First castings are inspected for dimensional accuracy, surface quality, and material properties. - Full-scale production

Approved designs proceed to batch production in selected foundries in Mexico. - Quality verification

Each batch undergoes thorough inspection to ensure compliance. - Packaging and delivery

Finished castings are packaged securely and shipped worldwide.

Types of Foundry Services in Mexico

Redstone offers a variety of Mexico foundries services:

Cast Iron Foundries

Durable, heavy-duty components for industrial machinery, automotive parts, and structural applications.

Aluminum Casting

Lightweight, corrosion-resistant parts suitable for automotive, electronics, and consumer products.

Custom Foundry Services

Supports complex geometries, low-volume production, and prototype development.

High-Volume Production

Efficient batch production of standardized components while maintaining quality and consistency.

Available Finishes

Our foundries in Mexico partners provide a range of finishing options:

- Sandblasting and shot blasting

- Grinding and polishing

- Heat treatment for enhanced mechanical properties

- Painting and powder coating

- Machining and secondary operations

- Protective coatings for corrosion resistance

Applications of Foundry Components in Mexico

Components produced by foundry companies in Mexico are used in:

- Automotive and truck components

- Industrial machinery and equipment

- Agricultural machinery

- Pumps, valves, and fluid handling systems

- Energy and power generation components

- Tooling, fixtures, and custom machinery

These applications benefit from the strength, durability, and precision of Mexico foundries.

Advantages of Foundry Services

Foundry manufacturing offers several benefits:

- Ability to produce complex shapes and large components

- Cost-effective tooling and production

- Wide material compatibility including iron, aluminum, and alloys

- Excellent mechanical properties and durability

- Scalable production from prototypes to high-volume runs

- Efficient material usage with minimal waste

By leveraging Redstone’s engineering support and trusted foundries in Mexico partners, clients gain access to high-quality, reliable castings for demanding applications worldwide.

Our Foundries in Mexico Serve:

Get updates from Redstone Manufacturing

Learn more about our metal manufacturing company

Changed from Brochure to Newsletter on 8/12/24