#1 PLASTIC INJECTION MOLDING COMPANY IN CHINA

Redstone Manufacturing’s plastic injection molding facility in China is committed to delivering the best-in-class buying experience from start to finish. Continue reading on to learn more about our unique approach to the plastic injection molding process, and how our US-based sales-staff can help you optimize tariff costs, and demystify the buying process of plastic injection molding services in China.

PLASTIC INJECTION MOLDING IN CHINA – SIMPLIFIED

THE LIST OF PLASTIC INJECTION MOLDING COMPANIES IN CHINA IS ENDLESS…

With China’s plastic injection molding industry consisting of more than 1,000 manufacturers spread out from Shanghai to Beijing, and Guangzhou, the process of selecting a plastic injection molding vendor in China can be overwhelming. Here at Redstone Manufacturing, we simplify the buying process and reduce the risk of working with foreign manufacturers. With headquarters in the USA and plastic injection molding manufacturing facilities in China, our buyers receive guaranteed delivery backed by a US-based company with a US-based sales force they can trust. Combined with Redstone Manufacturing’s supply chain, tariff consulting, and diverse plastic injection molding production capabilities, the end result is significant cost savings and reduced risk during your plastic injection molding process from start to finish.

OUR PLASTIC INJECTION MOLDING FACILITY IN CHINA HAS THE FOLLOWING CAPABILITIES

| SIZES AVAILABLE | 20 grams to 10 kg |

| MATERIALS AVAILABLE | ABS, HDPE, LDPE, PE, PEEK, POM, PP and more. |

| TOLERANCE | +/- 0.008″ (0.203 mm) |

| LEAD TIME | 5-8 weeks |

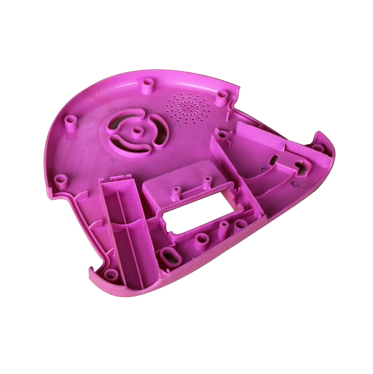

China Plastic Injection Molding: High-Quality Custom Plastic Components

Redstone Manufacturing partners with trusted plastic injection molding china suppliers to provide high-quality, cost-effective plastic components for a wide range of industries. Our plastic injection molding in china services cover custom prototypes, low-volume runs, and high-volume production, ensuring reliable quality and delivery. With Redstone, you gain access to experienced china custom plastic injection molding partners capable of producing complex, precise parts to exact specifications.

Plastic Injection Molding Process Description

Plastic injection molding is a versatile manufacturing process where molten plastic is injected under high pressure into a precision mold cavity. The material cools and solidifies to form the finished part. This process allows for the production of consistent, high-quality parts with intricate geometries and tight tolerances.

Redstone’s china plastic injection mold manufacturer partners employ advanced technologies including:

- Multi-cavity molds for high-volume production

- Temperature-controlled injection systems for precision

- Automated part ejection and quality control

- Post-processing including trimming, polishing, and assembly

- Inspection and testing for dimensional and material accuracy

These steps ensure each component meets functional and aesthetic requirements.

Why Choose Redstone for Plastic Injection Molding in China

Redstone Manufacturing is a trusted partner for custom plastic injection molding china services because we combine technical expertise, supply-chain reliability, and quality oversight. Advantages include:

- Access to vetted plastic injection molding service china partners

- Local quality inspection and engineering support

- Expertise in thermoplastics, engineering plastics, and specialty polymers

- Cost-effective production without compromising precision or performance

- Prototyping and low-volume testing before full-scale production

- Design-for-manufacturing guidance to optimize mold design and part function

- Logistics support for timely delivery

By working with Redstone, you can leverage the capabilities of china injection plastic mold manufacturers while ensuring reliable, consistent results.

How to Order Plastic Injection Molding Services

- Submit your design files

Provide CAD models, part drawings, material requirements, and tolerances. - Receive a detailed quotation

Redstone evaluates mold requirements, production volume, and finishing needs. - Tooling and mold development

High-precision molds are produced to ensure accurate reproduction. - Prototype or first-article production

Sample parts are manufactured and inspected for dimensional accuracy and surface quality. - Full-scale production

Approved designs proceed to batch production in the selected china plastic injection mold manufacturer. - Quality verification

Each batch undergoes inspection for material compliance, dimensional accuracy, and finish. - Packaging and shipping

Finished parts are carefully packaged and shipped worldwide.

Types of Plastic Injection Molding Services

Redstone offers a variety of plastic injection molding china capabilities:

Standard Plastic Injection Molding

Ideal for consumer products, household items, and industrial components.

Custom Plastic Injection Molding China

Supports unique designs, low-volume runs, and specialized parts requiring precise tolerances.

Engineering Plastic Injection Molding

High-performance components for automotive, electronics, and medical industries.

Multi-Material and Overmolding

Enables production of parts combining multiple materials or colors in a single mold.

Prototype and Low-Volume Production

Efficient prototyping and small-batch manufacturing to validate designs before scaling.

Available Finishes

Plastic injection molded parts can be delivered with a variety of finishes:

- Polishing and trimming

- Texturing or matte finishes

- Painting or powder coating

- Assembly and insert molding

- Electroplating for decorative or functional purposes

- Custom finishing per project requirements

Applications of China Plastic Injection Molded Components

Plastic injection molding in china is used in numerous industries, including:

- Automotive components and housings

- Consumer electronics and appliances

- Medical devices and surgical tools

- Industrial machinery and equipment

- Packaging and containers

- Prototypes and custom parts for R&D

- Toys, gadgets, and household products

These applications benefit from the precision, consistency, and versatility of china custom plastic injection molding.

Advantages of Plastic Injection Molding

Plastic injection molding provides multiple benefits for manufacturing:

- High precision and repeatable tolerances

- Ability to produce complex geometries and intricate details

- Fast production for both small and large volumes

- Cost-effective tooling and material usage

- Versatility with various plastics and engineering polymers

- Minimal post-processing required for near-net-shape parts

With Redstone’s engineering support and trusted plastic injection molding service china partners, customers receive cost-effective, high-quality components suitable for demanding applications worldwide.

Get updates from Redstone Manufacturing

Learn more about our metal manufacturing company

Changed from Brochure to Newsletter on 8/12/24