Investment Casting Services

Redstone Manufacturing provides investment casting services utilizing grey iron, stainless steel, alloy steel, aluminum, carbon steel, and more. Our precision lost wax casting shops produce ISO9001 quality investment castings with fast turnaround times at affordable rates.

OUR PORTFOLIO OF

Investment Casting Companies

Finding a reliable investment casting company in the United States doesn’t need to be difficult or expensive. Redstone Manufacturing is uniquely positioned to help serve your needs with ISO9001 certified investment casting facilities in China and India, as well as headquarters in the United States. We reduce the risk of working with foreign entities and help companies secure the best manufacturing prices for their investment casting services by utilizing Redstone Manufacturing’s diversified supply chain.

Investment casting applications

Investment casting is typically used for smaller precision parts that are difficult to produce using other casting methods. Investment casting services allow for design flexibility and a wider choice of alloys, making it an attractive option for manufacturing. Investment casting is used industries such as aerospace, automotive, and dentistry, to name a few, have seen the value of utilizing this method to suit their needs.

Common Products &

Use Cases of Investment Casting

- Triggers

- Medical Equipment

- Automotive Parts

- Turbine Blades

- Hand Tools

- Lock Parts

- Aerospace Parts

- Pipe Fitters

Investment Casting Vs. Sand Casting

Both methods have been around for centuries, but the final product will dictate which option is best to use.

Sand Casting Services

- A range of different parts or several of the same part may share a mold.

- New molds are easy to remake.

- Higher casting weight limit.

- Greater ease of changing design.

- Difficult to cast parts with internal voids.

Investment Casting Services

- Ceramic mold (initial investment) is destroyed to get parts.

- Better equipped to make small, intricate parts.

- More complex and labor-intensive.

- Hundreds of small parts can be cast at once.

- Excellent surface finish.

- Greater design freedom.

Investment Casting Services in US

Redstone Manufacturing delivers high-precision investment casting services for clients seeking complex geometries, excellent surface quality, and exceptional dimensional accuracy. Our ISO-certified foundries supports projects of all sizes, from small intricate parts to medium-volume industrial components. Whether you need stainless steel, aluminum, carbon steel, or specialty alloy castings, our investment casting service provides consistency, repeatability, and long-term performance across every industry.

The Investment Casting Process

Investment casting, also known as lost-wax casting, is a manufacturing process that allows the creation of highly detailed metal components. The process begins with producing a wax pattern identical to the final part. These wax patterns are assembled on a tree, coated with ceramic slurry, and repeatedly dipped to build a strong ceramic shell. After curing, the wax is melted out, and molten metal is poured into the hollow ceramic mold. Once the metal solidifies, the shell is broken away to reveal the cast component.

This process enables extremely tight tolerances, smooth surfaces, and complex internal or external features that are difficult or impossible to achieve using other casting methods. Redstone’s investment casting services follow strict temperature control, advanced shell-building techniques, and precision pouring to guarantee consistent, high-quality results.

Why Choose Redstone Manufacturing

Redstone Manufacturing stands out as a premium provider of investment casting services due to our unique combination of engineering expertise, production capabilities, and strict quality control.

- Broad Material Capabilities: Stainless steel, steel, aluminum, nickel alloys, cobalt alloys, brass, bronze, and custom materials

- Advanced Engineering Support: Our team optimizes part geometry, gating systems, tolerances, and alloy selection

- Precision Tooling: High-quality wax injection dies designed with CNC machining and 3D modeling

- Foundry: Multiple international locations ensure consistent supply, competitive pricing, and flexible capacity

- Fast Prototyping: 3D-printed wax patterns enable rapid prototype development without tooling

- Rigorous Quality Control: Dimensional inspection, X-ray, magnetic particle testing, chemical analysis, and hardness testing

By choosing Redstone, you gain a reliable partner capable of delivering complex, high-tolerance parts with outstanding repeatability.

How to Order Investment Casting Services

We make it easy to partner with Redstone for your investment casting service needs.

- Send Your Design: Provide your 3D model or technical drawing for engineering review

- Receive a Detailed Quotation: We outline tooling costs, material options, and lead times

- Wax Pattern and Tooling Production: Patterns are produced using injection tooling or 3D printers

- Ceramic Shell Building and Metal Pouring: The mold is created, cured, and filled with molten metal

- Cutting, Finishing, and Machining: Parts are removed from the tree, cleaned, machined, or heat-treated as needed

- Inspection and Delivery: Final inspection ensures compliance with specifications before shipment

This structured workflow guarantees transparency, predictable lead times, and consistent part quality.

Investment Casting Subtypes

Redstone offers various investment casting service options to suit different technical requirements.

Traditional Wax Injection Investment Casting

Wax patterns are created using precision injection dies, ideal for long-term production and consistent repeatability.

3D-Printed Wax Pattern Investment Casting

Patterns are printed using additive manufacturing, enabling complex shapes, rapid prototyping, and low-volume production without tooling.

Vacuum Investment Casting

Used for high-performance alloys that require controlled atmospheres to prevent contamination or oxidation.

Rapid Investment Casting

Accelerated production cycles for time-sensitive projects, combining fast pattern production with streamlined shell-building techniques.

Our team helps you select the most suitable method based on your material, geometry, and production volume.

Product Finishes

Investment cast parts can undergo a wide range of finishing operations depending on mechanical, cosmetic, or functional requirements.

- As-Cast Finish

- Machining for Tight Tolerances

- Shot Blasting or Sand Blasting

- Polishing or Mirror Finishing

- Heat Treatment (solution treatment, aging, hardening)

- Powder Coating

- Painting

- Anodizing for Aluminum Components

- Electroplating (nickel, chrome, zinc)

These finishing options enhance corrosion resistance, appearance, and mechanical performance.

Applications and Industries

Investment casting is widely used to produce precise, durable components across multiple industries.

- Aerospace: turbine blades, structural components, aerospace fittings

- Automotive: gears, brackets, housings, engine components

- Medical: surgical tools, implant components, precision instruments

- Defense: weapon components, military-grade hardware

- Industrial Machinery: pump parts, valves, impellers, connectors

- Energy: turbine parts, power generation hardware

Redstone provides highly reliable, repeatable castings for critical applications where precision and strength matter most.

Advantages of Investment Casting

Using investment casting services offers numerous benefits.

- Excellent dimensional accuracy and tight tolerances

- Smooth, high-quality surface finish

- Ability to achieve extremely complex geometries

- Reduced machining requirements

- Supports thin walls and intricate internal features

- Works with a wide range of metals and high-performance alloys

- Ideal for medium-volume production and parts requiring exceptional detail

Redstone’s advanced processes and engineering expertise ensure optimal results, whether you need intricate prototypes or high-precision production runs.

Investment Casting Process

Create Pattern

Involves creating a wax pattern that has the same specifications as the part which also allows for shrinkage.

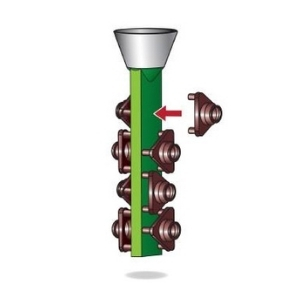

MOUNT WAX PATTERN & CREATE TREE

Mount multiple wax patterns to create a tree with gates that connect each pattern.

CREATE MOLD SHELL

The wax pattern tree is dipped in ceramic, allowed to dry, then re-dipped until a shell of desired thickness is achieved.

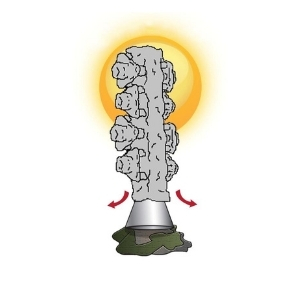

Wax Removal

Assembly is heated to remove wax pattern until only ceramic remains.

Melt & Cast

Mold is preheated then filled with molten metal to form the part casting.

Final Operations

After cooling, the shell is broken to reveal the final part. Runners and gates are removed, and some grinding, machining and sandblasting might be required.

FAQ's ABOUT OUR INVESTMENT CASTING SERVICES

Investment castings require more preparation and expense. They also don’t allow for large production runs. This process also has smaller size limitations compared to other casting methods.

Investment casting produces a near-net shape and is an extremely accurate process.

Compared to other casting methods, it is considered more expensive because of the extensive preparation of the ‘tree’ and multiple molding steps. However, most other methods are incapable of producing smaller and more intricate designs usually obtained through investment casting.

Investment casting is a versatile casting method that can utilize most metals which can be melted and poured. The selected metal type will depend on your product specification needs. Contact our sales department for a free consultation on metal selection if neccessary.

INVESTMENT CASTING MATERIALS

Redstone’s Manufacturing’s investment casting services can utilize seven different metal material types – grey iron, ductile iron, stainless steel, alloy steel, carbon steel, aluminum, and copper.

Grey Iron

Investment Casting

Commonly used for investment casting because of its good machinability and low cost. It is a popular choice when a metal with good corrosion resistance and less solidification shrinkage is desired.

Ductile Iron

Investment Casting

Known for its erosion resistance, surface hardening ability, and strength to weight ratio. Its net ductile shape allows engineers additional design freedom and its attractive manufacturing cost makes it a popular choice.

Stainless Steel

Investment Casting

Prized for its durability, resistance to wear, and corrosion. Moreover, it retains its excellent qualities, typically without requiring additional coating or plating.

Alloy Steel

Investment Casting

Commonly used in industrial applications that require corrosion-resistant, tough metal. Additional elements are added to alloy steel to increase hardness and vary based on the intended use of cast parts.

Carbon Steel

Investment Casting

Commonly used when parts are required to perform under great pressure and resistance to wear. As their name suggests, carbon is what provides extra toughness, and this alloy can produce parts with a wide range of applications and properties.

Aluminum

Investment Casting

Among the most popular metals used for investment casting, and for good reason. Aluminum has one of the best high strength to low weight ratio.

Copper

Investment Casting

Commonly used in high wear and high corrosion applications. It is a less popular alloy because price fluctuations drive up the cost of waste.

Companies that use our investment casting solutions

Get updates from Redstone Manufacturing

Learn more about our metal manufacturing company

Changed from Brochure to Newsletter on 8/12/24